Lifespan of UPS Batteries – Riello Whitepaper

Written by

Introduction

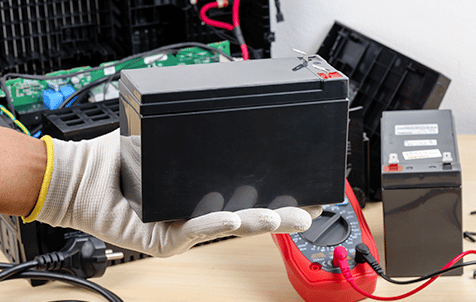

The battery system connected to an Uninterruptible Power Supply (UPS) is key to its continuous operation. Without a well-maintained, quality battery system that will perform when required, the UPS is practically useless.

For a UPS, battery failure is as serious – and unwanted – as any mains power outage. Batteries represent a significant share of the total cost of a UPS too. Good upkeep is essential.

Ignoring maintenance and/or service recommendations and letting the battery system fall into a poor state increases the risk to both the critical load and business continuity.

Although alternatives such as lithium-ion are becoming more popular and commercially viable, the majority of UPS today still use traditional sealed lead-acid batteries.

These cells have low energy-to-weight and energy-to-volume ratios – they are big and heavy – but they do provide high surge currents, so are ideal to provide backup during a mains failure or start up a generator.

UPS batteries tend to have either a 5 or 10-year design life. Yet performance begins to deteriorate from the moment dioxide paste is applied to its lead grids in the factory.

Due to their complex nature, each battery string and cell behaves slightly differently and has a unique rate of deterioration, which is influenced by a variety of external factors.

Battery Design Life Versus Service Life

Even though battery manufacturers will state their battery has a design life of 5 or 10 years, under EUROBAT (Association of European Automotive and Industrial Battery Manufacturers) international guidelines a battery is considered at the end of its service life when its capacity falls below 80% of its original.

In effect, this means that a 10-year design life battery will last for 10 years – assuming perfect operating conditions – but its performance will significantly reduce over time to a degree where it isn’t safe to use in a UPS system.

Of course, no installation is ever perfect – this would be technically impractical, not to mention cost-prohibitive. Actual battery service life depends on several factors, including operational and storage temperatures, discharge levels, and how many times they are called into action.

Excluding these external influences, the operational capacity of a 10-year design life battery will drop below the required 100% capacity at year 6 (Figure 1). Over the remaining 4 years, the capacity will reduce to 80%, while the autonomy of the UPS will reduce too.

This helps explain why it’s become accepted best practice to replace 10-year design life batteries in years 7 or 8.

This takes into account all the external factors that can reduce battery life and provides a safe enough margin for potential failure, without compromising the risk to the protected load. Comparable drop-offs in performance over time are also seen in 5-year design life batteries, which are typically replaced in either year 3 or 4.

Bringing together some of the industry’s most experienced and talented people, we are committed to improving standards across the emergency power landscape through reliable and efficient delivery of all our services.

Get in Touch With Us

Contact Info

Visit Us

Sheffield Road, Chesterfield, S41 9ED